If you're in the maritime industry, then you know how important it is to have reliable and high-quality equipment on your vessels. One critical component of any ship is the windlass brake, which is responsible for controlling the speed of the anchor chain as it's being deployed or retrieved. To ensure the safety and efficiency of your operations, it's essential to have top-notch windlass brake linings in place. In this blog, we'll be discussing everything you need to know about

windlass brake linings in UAE and why they're crucial to your vessel's performance.

What are windlass brake linings?

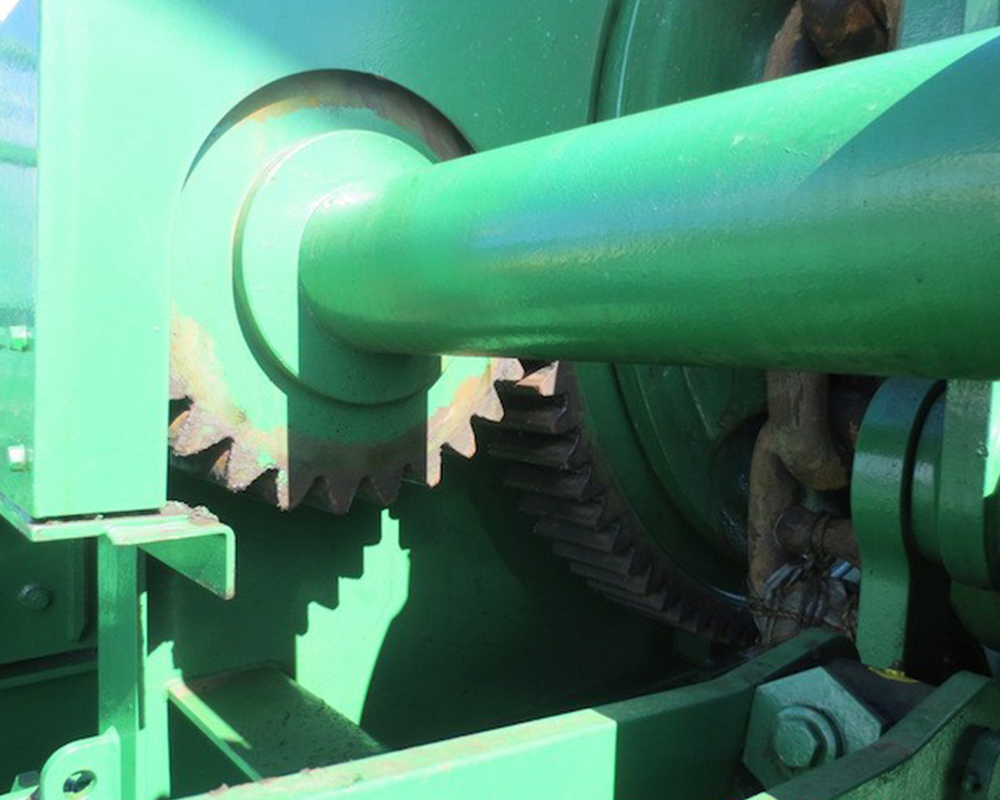

A windlass brake is essentially a friction brake that controls the movement of the anchor chain. It's composed of a series of brake pads that press against a rotating drum, effectively slowing down the chain's movement. These pads, commonly known as windlass brake linings, are typically made from materials like asbestos, ceramic, or organic compounds. Their primary function is to withstand the high temperatures and pressures that are generated during braking while maintaining a high level of friction.

Thing to Consider When Getting Windlass Brake Linings in UAE

Now, when it comes to windlass brake linings in UAE, there are several things to consider. Firstly, it's important to ensure that you're sourcing your linings from a reputable supplier. The UAE is home to numerous companies that specialize in the manufacturing and distribution of windlass brake linings. However, not all of them are created equal. You'll want to do your research and choose a supplier that has a proven track record of delivering high-quality products that meet industry standards.

Another thing to keep in mind is the specific requirements of your vessel. The windlass brake linings you choose should be compatible with your windlass system and designed to handle the weight and size of your anchor chain. Depending on the type of vessel you have and the nature of your operations, you may need to opt for linings that are more durable or have higher friction coefficients.

Benefits of Using Windlass Brake Linings in UAE

1. Increased Safety

The primary benefit of using

windlass brake linings UAE is increased safety. Without reliable and high-quality brake linings, the anchor chain can become difficult to control, leading to accidents and injuries. Windlass brake linings are designed to withstand the high pressures and temperatures generated during braking, ensuring that the anchor chain can be safely deployed and retrieved.

2. Improved Efficiency

Another benefit of using windlass brake linings is improved efficiency. When the brake linings are functioning correctly, they provide a consistent level of friction, allowing for smooth and efficient movement of the anchor chain. This ensures that the ship's crew can perform their tasks quickly and with minimal downtime, increasing overall operational efficiency.

3. Cost Savings

Using windlass brake linings in UAE can also lead to cost savings. High-quality brake linings are designed to last for an extended period, reducing the need for frequent replacements. Additionally, by ensuring that the windlass system is functioning at its best, you can prevent costly repairs and maintenance down the line.

4. Versatility

Windlass brake linings UAE supply come in various materials, making them versatile and adaptable to different vessels and operations. For instance, if your vessel operates in harsh environments with high temperatures, ceramic linings may be a better option than organic compounds. Similarly, if your vessel has a large anchor chain, you may need to opt for more durable linings. By choosing the right material, you can ensure that your windlass brake is optimized for your specific needs. By understanding the pros and cons of each material, you can choose the one that best suits your needs.

5. Compliance with Industry Standards

Using windlass brake linings that meet industry standards is essential for compliance and safety. In UAE, there are several regulations that govern the use of windlass brake linings in the maritime industry. By using high-quality linings from reputable windlass brake linings UAE suppliers, you can ensure that your vessel is compliant with these regulations and that you're operating safely and responsibly.

6. Durability

Windlass brake linings are subject to high pressures and temperatures generated during braking. As such, they need to be made of durable materials that can withstand the rigors of daily use. Using high-quality brake linings ensures that they can last for an extended period, reducing the need for frequent replacements.

Maintenance of Windlass Brake Linings in UAE

1. Regular Inspections

The first step in maintaining windlass brake linings is regular inspections. Inspections should be performed by a qualified technician and should be conducted at regular intervals. During these inspections, the technician should look for signs of wear and tear, such as cracks, glazing, or discoloration. They should also check the thickness of the brake lining and ensure that it's within the manufacturer's recommended specifications.

2. Cleanliness

Another important aspect of maintaining windlass brake linings is cleanliness. The

windlass brake linings UAE can become contaminated with debris, oil, and grease, affecting their performance. It's essential to keep the brake linings clean and free of any contaminants. Use a soft-bristled brush to remove any debris or dirt from the brake linings. Avoid using harsh chemicals or abrasive materials that could damage the brake linings.

3. Lubrication

Lubrication is also a critical part of maintaining windlass brake linings. Proper lubrication can help reduce friction and prevent premature wear of the brake linings. Use a high-quality lubricant that's recommended by the manufacturer, and apply it according to the instructions. Be careful not to over-lubricate, as this can lead to slippage and reduced braking efficiency.

4. Temperature Control

Windlass brake linings UAE can be affected by high temperatures, which can cause glazing and reduced braking performance. It's essential to control the temperature of the windlass system to prevent excessive heat buildup. This can be achieved by ensuring proper ventilation and avoiding prolonged or heavy use of the windlass system.

5. Replacement

Lastly, windlass brake linings will eventually need to be replaced. The frequency of replacement depends on several factors, such as the vessel's usage and operating conditions. It's essential to replace brake linings before they become too thin, as this can lead to reduced braking efficiency and safety hazards. Always use high-quality brake linings that meet industry standards and are recommended by the windlass system manufacturer.

Investing in High-Quality Windlass Brake Linings: Cost Savings and Longevity

Investing in high-quality

windlass brake linings in UAE is a wise decision for any ship owner or operator. While it may require a larger upfront investment, it can lead to significant cost savings and increased longevity in the long run.

Choosing the right windlass brake linings that meet the specific requirements of your vessel and complying with UAE regulations can help ensure safe and efficient operations while reducing the risk of costly repairs and downtime.

By partnering with

Viking Emirates brake linings suppliers in UAE and performing regular maintenance, you can extend the lifespan of your windlass brake linings and contribute to overall cost savings. Remember, when it comes to the safety and efficiency of your vessel's windlass system, the investment in high-quality windlass brake linings is worth it.